jonh : robots :

fiat : experiments

Experiments

Experiment 1

This experiment was designed to measure the reliability and repeatability

of the paper pickup and drop mechanism. For each observation, the

robot was placed at a known location, with a piece of paper placed

below it at approximately the correct location for pickup. The robot

was commanded to pick up the paper, rotate 180 degrees, drop the

paper, and rotate 180 degrees to its initial position.

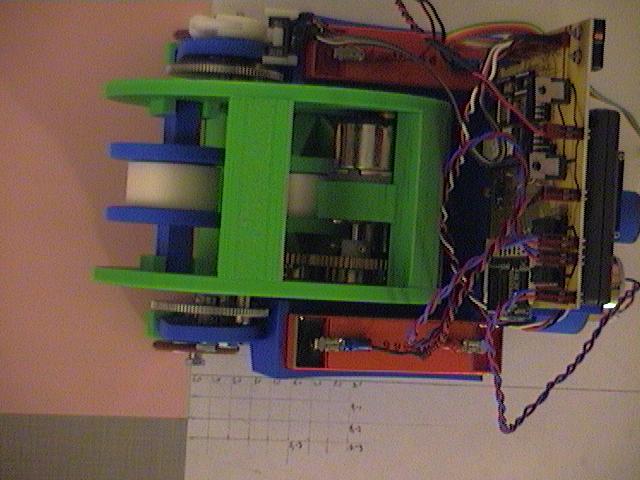

The experimental setup

After the motion was complete, I measured the position of one corner of the

paper (on the grid visible in the photograph), and measured the intercept

of one edge of the paper along a vertical line (beyond the right edge of the

photograph).

The procedure was repeated 141 times.

The observations and analysis are available in this

table.

Qualitative observations.

Several failure modes appeared during the course of the experiment.

- Failure to pick up the sheet or hold onto the sheet during rotation.

- This happened frequently during the first 84 experiments, at which

point I realized that the cam was twisting, which it shouldn't have done

by its design. I found a loose set screw on the shaft that couples the

left and right side cam gears, and tightened it. After that, this failure

mode never recurred.

- Failure to cleanly release the paper at the end of travel.

- This happened in 8 of the 58 cases after the loose setscrew was

tightened (14%).

The paperDrop() primitive includes a wiggle to loosen the paper in

just this case; in all eight cases, the paper ended up near enough to its

goal that it was measurable; these failures contribute to the position

error reported below.

- Cam phase error.

- The sensor that detects the phase of the cam assembly signalled

``end of travel'' incorrectly in 5 of the 58 final observations (9%).

Four times, the paper was never picked up or never released, and the paper

ended up nowhere near the target zone. Those four observations do not

contribute to the reported position error, and instead are counted as

failures. This was the only source of failure (paper landing nowhere near

the target) after the set screw was fixed, leading to a 93% success rate.

Reliability. Over the 141 experiments, the paper ended up in the

measurable target region 113 times, giving an 80% success rate.

Over the 58 experiments performed after the set screw was tightened,

the paper ended up in the measurable target region 54 times, giving

a 93% success rate.

Repeatibility.

For each observation, I derived the angle of the paper from the vertical

intercept value. Then I computed the mean and standard deviations of the

position vector and the angle value.

The mean is fairly uninteresting. It represents systematic error; error that

can be compensated for in software by calibrating the odometry to the measured

mean position.

The standard deviation, on the other hand, reflects the how repeatably the

robot can place a sheet of paper near its target.

Over the 113 successful runs, one standard deviation was less than

0.89 cm positional error and 4.7 degrees rotational error.

Over the 58 runs performed after the set screw was tightened,

one standard deviation was less than 0.51 cm positional error and 3.3 degrees

rotational error.

Conclusions.

We can conclude the following:

- Assuming the robot can navigate accurately, the robot can position paper

fairly accurately (within half a centimeter and a few degrees).

- Once the set screw was tightened, there was only one failure mode

that prevented the paper from reaching the target area.

The failure was due to a faulty cam sensor. Because this device

senses the internal state of the robot, it should be possible to replace

it with a much more reliable encoder.

- The only other directly observable source of error was ``sticky release.''

A redesigned cam mechanism in which the wheels are closer to the sticky foot

should reduce this problem by taking up some of the slack in the paper.

Experiment 2

This experiment was designed to learn how well the robot could manipulate

paper, one sheet above others on the desk.

We commanded the robot to lift a sheet of paper from a stack, navigate

through 60 centimeters and a 90 degree turn, deposit the paper, and return

to its initial position; this sequence was repeated three times to move

a stack of three sheets to make a new stack at the goal position.

This experiment was performed when the set screw was still loose (it happened

chronologically before experiment 1).

This is the experiment that appears on the video.

Other than the sorts of errors observed in experiment 1, I

also observed that the robot, in the process of picking up the top sheet

on a stack, shifted the whole stack on the desk. This had two consequences:

First, the stack was now in a different place, so when the robot returned,

the stack was not where it was expected. Second, this would sometimes result

in a second sheet being exposed and sticking to the foot. It wasn't stuck

very well, and tended to fall off at random places en route to the goal.

The cause of the stack-scooting problem is that

when the cam moves horizontally, the robot's length is effectively increasing.

Because the front wheel is not back-driveable and has a high coefficient

of friction, the paper gives instead. An alternative design with the back

wheels driven and the front wheel free might solve this problem.